reloading 9mm with 115 gr. Oregon Trails LRN and 231 powder

so i got my Browning High-Power back from the factory a little while ago, cured of its ills. since i had a stack of boxes of ammo i bought for another gun, i used them up instead of rolling my own. now that the store boughts are history, it's time to go back to the round my gun loves best.

since building my reloading bench, i've stacked a ton of reloading stuff on it. here's the pile of bullets awaiting their turn in the press

hmm. let's see. looks like about 2000 rounds of 115 grain 9,mm, 2000 200 grain 45 ACP, about 1500 rounds of various weights for the 45 COLT, a 1000 rounds of 170 grain flat points for my 30-30, 2000 125 grain remington golden sabers for the 357, 3000 148 grain hollowback wadcutters for the 38 special, 250 70 grain Speer TNT hollowpoints in .243, and an odd collection of various 9mm i experimented with.

actually, i'm guessing at quantities, because a lot of the boxes have been opened and used. that's just the "published amount". to see different views of the bullet storage, visit my flickr set Things that go BANG

before getting into the actual reloading, let us talk about one of the main components: BRASS. All reloading manuals have tons of info about what to look for in your brass. splits, bulges, blown primers. so i'm not. but there are things they don't tell you.....

a word about cases. i am a range rat. i'm also a scrounger. i am glad there are only a few of us that reload, because the number of folks that just leave their brass behind keep me in reloading components. BUT you get what you pay for. in this case, there are some things to be aware of when scrounging cases that you haven't actually shot yourself. first, if it's an aluminum or steel case, leave it there. neither one is designed to be reloaded and are single use casings. if the case is creased on the sides, leave it there. you don't need the potential for damage or injury from using a weakened case. if it's military, leave it there. usually you can tell a military round because even if there is something stamped into the head, it probably won't be the caliber. why not use military casings? the primers are crimped in place, and to remove the primer and swage out the crimp is a pain in the ass, and the gear needed is just another expense for a sometime used piece of equipment. there are usually so many ammo casings left behind by others that dropping the military stuff isn't painful at all. why do you care if the primer is crimped in? you can damage your decapper, and possibly damage your primer assembly repriming. a visual, if you please. i took one military case, decapped it, and attempted to prime the shell to demonstrate the typical outcome of using military brass that hasn't had the pocket reswaged. here's what usually happens when you do that:

so for this ammo, i am using

I'm also using Oregon Trails lasercast 115 grain hardcast lead round nose bullets.

all of the prep work takes time, so that first thrown bullet is a reward.

when reloading, most sizing dies will straighten out a lot of the case mouth deformations one will find with scrounged ammo. just don't use dinged cases. bad juju. here's an example of a flattened case that presents no problems reloading. this is a very mild deformation, and most presses can handle much much worse. it's in station 1 the lowest of the cases in the image

a little patience, and before you know it

when building ammo, the first thing i do is measure the first 3 rounds for powder weight. then i check about every 20 rounds or so. the second thing i do is check for overall length, in this case 1.10 inches

after throwing 100 rounds, i check all the rounds by standing them up in a metal tray. this will tell me if there are any problems with seating the primers deep enough. important in an auto, even more so if loading revolver rounds. a shallow primer could cause the weapon to malfunction, or even worse.

next, i box my ammo, or put it into ziplock bags.

check out this closeup.

so what did a couple of hours in the shop get me? how about 700 rounds of custom built, kick ass, consistent ammo to blaze away with. that's what it got me.

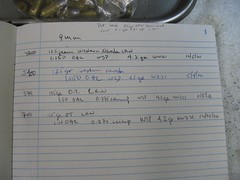

and since i'm such a geek, i always try to keep track of the ammo i've built. this is a new book, started in 2001 when the other was filled. you know what they say... it ain't done until the paperwork is finished!

and while reloading i listened to the following cds

music to reload by

DJ Shadow: Preemtive Strike

Mike Oldield: Tubular Bells 2

Bad Company: 10 from 6

Pink Floyd Meddle

edit: went back out and reloaded some more. 200 rounds of 9mm, and 300 rounds of 45 acp with 200 grain oregon trails semi-wadcutters. once you get going, it's hard to stop.

tunes to reload by redux:

Tom Waits: Closing Time

Andreas Vollenweider: White Wind

Leo Kottke: Standing in My Shoes

and finally

Putumayo Presents Acoustic Brazil

Labels: 9mm, ammo, Browning Hi-Power, guns, reloading

5 Comments:

Actually a question, since it sounds like you you have experience with 9mm.

I just changed to Dillon dies and find that with moderate presssure I can force JHP bullets in loaded ammunition back in the case. Is this a problem? I did not notice this when I was reloading 9mm before I startedagain recently.

I like my Hi-Power too.

Missile Guy

i gather from what you are saying is you put a commercially produced round in the press, and by stroking the lever, the bullet will reseat to the depth of the die setting.

no problem there. if your press isn't strong enough to push a bullet into a brass cylinder that has been crimped, get another press. the bullet is only held by the tension caused by crimping, or deforming if you will, the case around the bullet.

now, if you can press down on your ammo on a benchtop, bullet down, and get it to move back into the case, you may have a problem.

a tip. nothing is foolproof, but setting your crimp die to compress the case to the SAMI specs listed in your reloading manual will go a long way towards insuring your ammo will feed properly, and not have the bullets shift in their cases during recoil.

another tip: get a decent Factory Crimp die for the final crimp. i use Lee Factory Crimp dies in all the calibers i reload. this is a relatively new thing for me, but i am now a believer. use your seating/crimping die to just seat the bullet, and use a crimp die to set the final diameter. i like to think i made good ammo before, but the stuff i've cranked out since adding one last step (the crimp die) have improved my final output tremendously. i've a lot less rejects in the go/no go gage since converting. as in NONE.

happy reloading.

feel free to ask questions. i'm no expert by any means, but i've learned a few things along the way. i must say though that there is nothing better than a good reloading manual, that you've read and use!

Hi. Thanks for this post. I am ready to start purchasing reloading supplies for my 9mm and this was very informative. Could you possibly recommend a good reloading manual for beginners? I'm looking for something that is easy to understand and will take away some of the apprehension of reloading.

Thanks again

most of the bullet manufacturers and powder manufacturers have manuals. i'd suggest the manual for the reloading press you get as the best starting point. RCBS and Dillon both have great instructions. RCBS is also associated with SPEER, so a SPEER reloading manual (i think the latest is #13) would be a great addition to your bench. Lyman's reloading manuals are also great references.

there are three things you need to load safely. a fundamental base knowledge of what you are doing, which you can get by diligently reading everything you can get your hands on BEFORE you start, a decent scale that will give you down to the 0.1 grain adjustments, and a decent vernier caliper. i have an old Starrett dial caliper, but there are a bunch of really good, relatively inexpensive digital ones now. if i ever need to replace it, that's what i'll be getting.

oh, and one thing more. and this is said in all seriousness: don't experiment with powders and depths. use the published dimensions and amounts. at least until you've reloaded a couple thousand rounds, and shot them. i've met several IDIOTS that think making their own blend based on burn rates is a good idea. yeah, if you have a strain gage, and you are testing in a purpose built receiver, and if you have enough experience to know when enough is enough. there is a dude i met years ago at the range that heard i was thinking about getting into reloading. he held up his 3 finger hand, and gave me that same piece of advice.

another thing, since i'm on the subject of advice. gather your cases as you shoot them, and look at the condition. is the case really discolored, due to blowback? maybe your bullet size is too small. it happens sometimes that the gun throat is too big, or your bullet is sized too small. are there cracks or splits in the case? is the primer flattened or cratered? those are terms you have to be familiar with from reading before starting.

remember, that thing you put your fresh handrolls in is just inches away from your face, held in your hands. being careful isn't a choice, it's mandatory

feel free to email me if you need any advice. that, i have lots of. what is worth is purely up to you to decide.

I think more information should be provided in the blog!!bullet manufacturers and powder manufacturers have manuals.

Post a Comment

<< Home